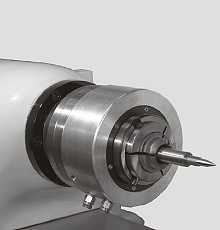

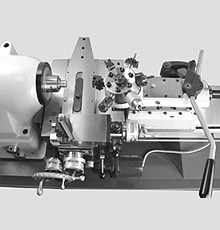

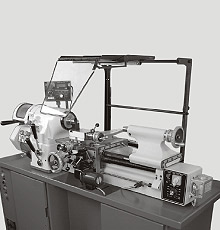

Model CTL-27EVS is a toolmaker lathe with a variable speed spindle that can reach up to 4000 RPM, a 5C collet system that can hold various shapes and sizes of workpieces, and a compound slide that allows for X-Z axis movements. It is designed for machining small-diameter parts with high accuracy and performance.

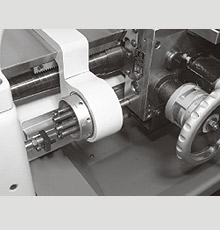

- High / Low speed quick change lever for convenience.

- High performance machining capability of shaft, chucking, or collet held workpiece.

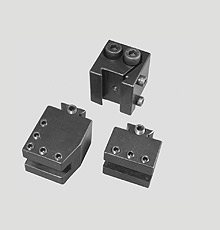

SPINDLE TOOLING, TOOLING HOLDER AND OPTIONAL EQUIPMENT FOR CYCLEMATIC HIGH SPEED. HIGH ACCURACY TOOLROOM LATHES

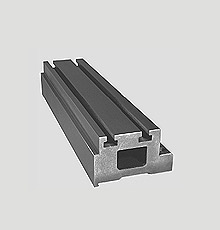

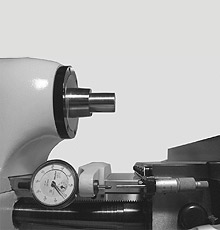

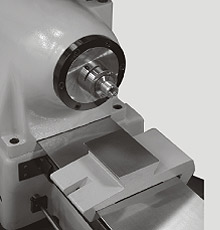

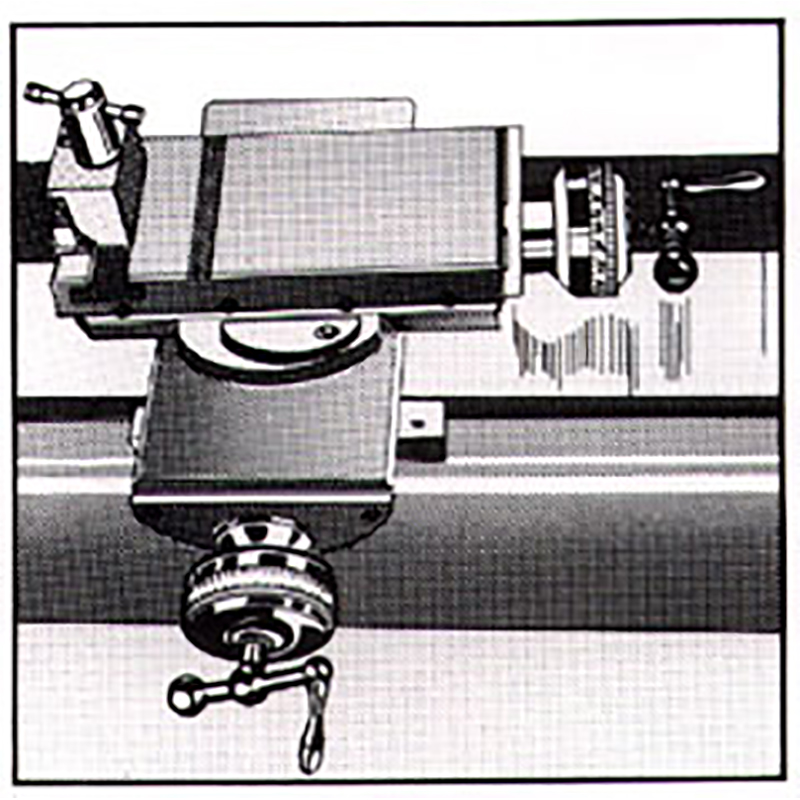

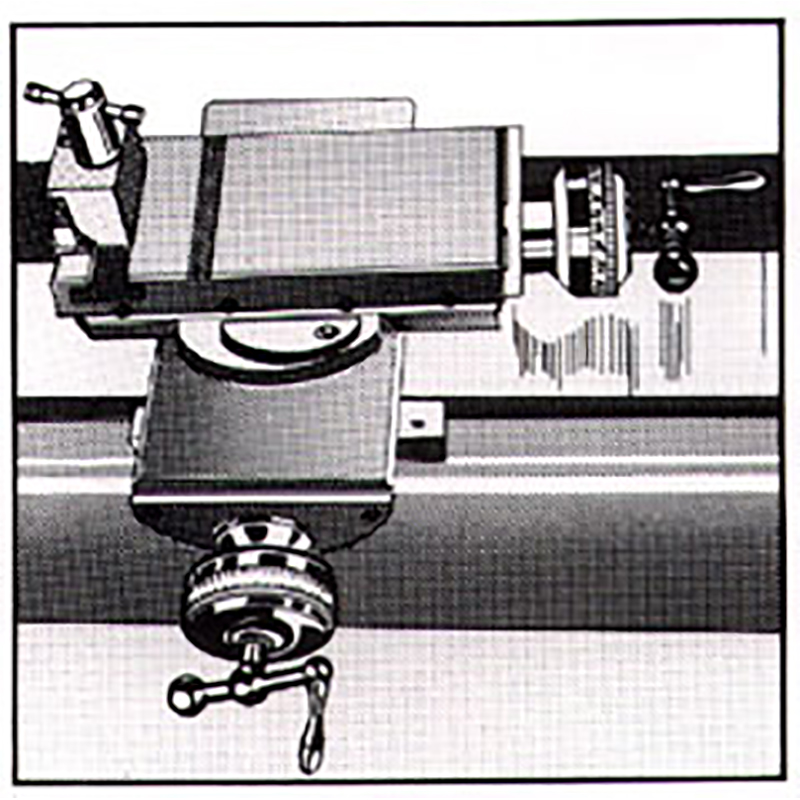

X-Z Axis compound slide standard on CTL-27EVS

The saddle slideway is coated with Turcite-B for maximum wear resistance.

The cross slideways have hardened and ground tool steel inserts for smooth accurate movement.

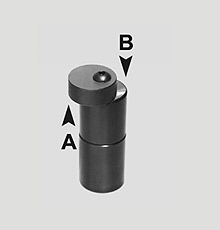

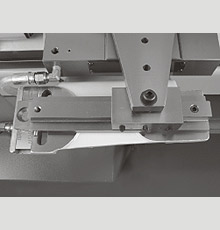

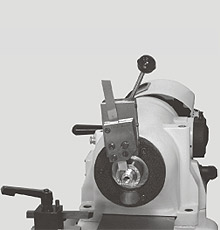

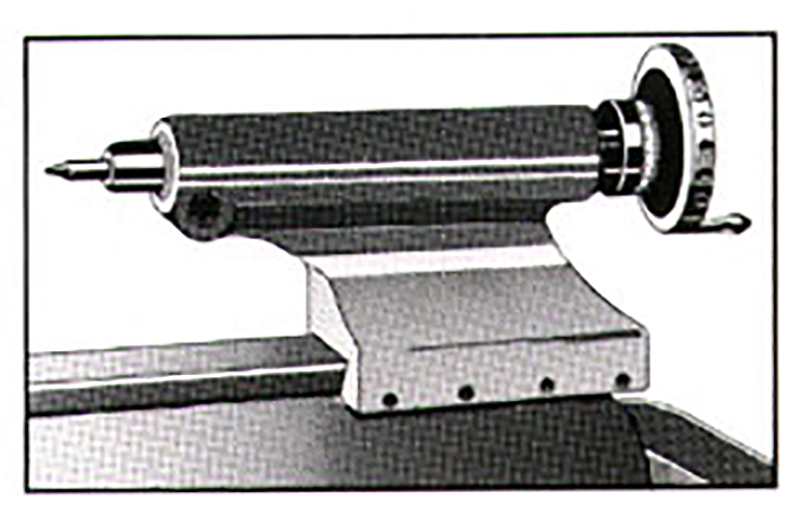

Screw feed tailstock standard on CTL-27EVS

The saddle slideway is coated with Turcite-B for maximum wear resistance.

The cross slideways have hardened and ground tool steel inserts for smooth accurate movement.

| MODEL | CTL-27EVS | |

|---|---|---|

| Spindle Capacity | With Chuck | 150 mm (6") |

| With Expanding Collets | 76 mm (3") | |

| With Round 5C Collets | 27 mm (1-1/16") | |

| With Hexagon 5C Collets | 22 mm (7/8") | |

| With Square 5C Collets | 19 mm (3/4") | |

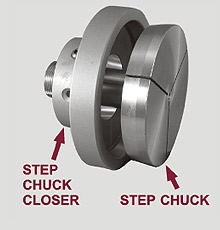

| With Step Chucks | 27 ~ 152mm (1-1/16-6") | |

| Spindle Nose Diameter | Ø55.5 mm (Ø2.189") | |

| Spindle Nose I.D/O.D | 5C (10°) / 4° Taper | |

| Spindle Speeds (Variable) | 50-4000 R.P.M. | |

| Inverter Spindle Motor | 3 HP | |

| Hole Through Spindle | 31.75 mm (1-1/4") | |

| Bar Stock Diameter (5C collet) | Ø27 mm (Ø1-1/16") | |

| Distance Between Centers | 380 mm (18") | |

| Swing Over Bed | 229 mm (9") | |

| Compound Slide Travel | X: 114 mm (4.488") / Y: 140 mm (5.512") | |

| Tailstock spindle diameter | 34.5 mm (1.358") | |

| Tailstock spindle taper | MT. #2 | |

| Tailstock spindle travel | 95 mm (3-3/4") | |

| Coolant pump | 1/8 HP. 220V. 3PH | |

| Main motor | 3 HP, 220V, 3PH | |

| Net/Gross weight | 990/1,364 lb. (450 / 620 kg.) | |

| Machine packing dimension | 1,910 × 850 × 1,790 mm (74" × 34" × 74") | |

| All dimensions, specifications and machine appearance are subject to change without prior notice. | ||

CONTENTS:

PURPOSES OF THIS MANUAL

This manual is an introduction to the CYCLEMATIC model CTL-27EVS SECOND OPERATION TOOLMAKERS MACHINE . If you thoroughly read, will get valuable information in the installation, operation and servicing of the CTL-27EVS CYCLEMATIC MACHINES.

The manual can be used for reference, because it is necessary to make minor adjustment for maintenance personnel and operators that have dealings with the model CTL-27EVS machine.

The model CTL-27EVS toolmaker lathe machines is built of extreme ease and safety of operation, the finest manufacturing and used high quality materials with the proper care and use, you are ensured trouble-free, accurate and economical operations for the life of the machines.

LIFTING MACHINE

Figure 1-Lifting Machine

When lifting the rope or cable should be arranged as shown figure 1. and checking to see whether the correct balance is obtained. Then insert pads of soft cloth between rope and machine edges.

The net weight of this machine approximate 540 kgs (990lbs). So, the rope or cable to be used for the work should be strong enough to withstand a weight of 1500 kgs (1000lbs).

A.) INSPECTION AND CLEANING OF MACHINE

An inspection to find some damaged portion which might have been caused by shock during the transportion, all surfaces of exposed machined are coated with a antirust liquid. Before moving turret and cross-slide, leadscrew, rack...etc, these surface should be thoroughly cleaned down the antirust liquid by soft brush and solvent. This is very important since it prevents any dirt and grit which may have accumulated on the antirust liquid from working under the sliding members and causing undue wear.

CAUTION : DO NOT USE COMPRESSED AIR TO CLEAN, WHICH WILL REDUCE THE MACHINE'S LIFE.B.) FOUNDATION, INSTALLTION, AND LEVELING

It is very important to obtain machine's accuracy that foundation and installation of machine are need. For the reason, a perfect foundation with proper thickness and pressure-enduring space must be provided. (In general case, a thickness of 30mm (12") is considered to be enough). The machine has six adjustable feet at the corner of the pedestal for leveling machine, it is necessary to use shims under pedestal feet. When adjust foot loosen set screw, then raiser or lower foot with a pin wrench so that all four feet rest on the floor. Tighten set screw to setting.

C.) WIRING

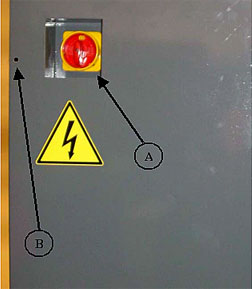

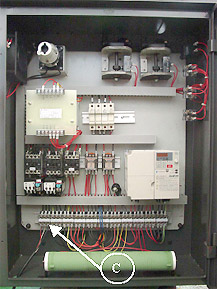

Turn cam switch A, (Figure 2) to "OFF" position, and loosen screw "B" (Figure 2), open the switch case cover connect your supply power source lines and ground connection to "C", (Figure 4). Secure switch case cover, turn cam switch "A" (Figure 2) to "ON" position.

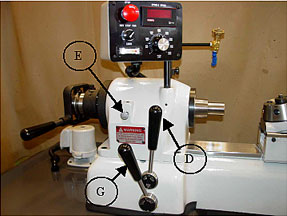

Place lever "D" (Figure 4), on lower position, pull out lock pin "E" (Figure 4) and push "START" button "C" (Figure 5), place lever "G" (Figure 4) on forward position. Spindle should rotate counterclockwise when viewed from turret end. If the spindle does not turn in the correct direction, push "STOP" BUTTON "H" (Figure 5) to stop machine, then, turn off the main power and interchange any two lead lines. This is to prevent changed speed motor from run in reverse at beginning.

D.) LUBRICATION

Special care on lubrication should be taken to maintain the life and performance of the machine for a long period. For the reason, must used a high quality or equal oil, and checked periodically to assure there are filled to the proper lever on the oil gage.

E.) SPINDLE CONTROL LEVERS

To change spindle speed, first, start spindle and release "H" (Figure 6), then turn the cam switch "S" (Figure 6) to the "FORWARDD" or "REVERSE" position, and push lever "D" Figure 7) to the "LOW" or "HIGH" position then push lever "G" (Figure 7) to the start position turn "F" (Figure 6) to increase speed.

FOR PROPER LUBRICATION OF DRIVE RUN THROUGH COMPLETE SPEED RANGE DAILY.

F.) LUBRICATION OF HEADSTOCK

The headstock spindle is mounted on precision preloaded ball bearings, the bearing are grease-packed for life and require no further lubrication.

G.) SPINDLE BRAKE

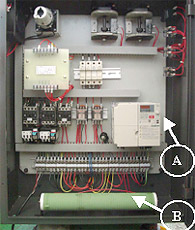

Inverter unit "A" is used to perform dynamic braking. In addition, discharge resistor "B" shortens braking time (Figure 8).

H.) BELT ADJUSTMENT

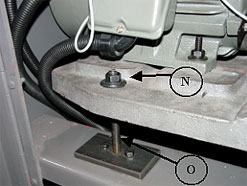

For allow belts to equalize their tension, must check belt tension. To tighten belts, first, loosen nut "N" (Figure 9) then turn screw "O" (Figure 9) to lower motor plate and to tighten belts equalize their tension.

I.) COLLET CLOSER REMOVAL

The collet closer in place without using collet when running the machine, that may damage the collet closer. So must remove the collet closer when using jaw chucks, face plates, fixture plates or other nose type fixtures.

When cleaning the machine need to remove the collet closer for prevent leading of chips between collet tube, and inside of spindle at rear end and collet threads. The methods of removal is described below :

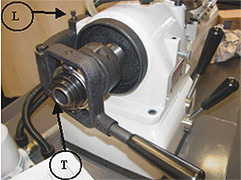

- First, pulling up and out link pin "L" (Figure 10) which is easy to pull out and up with fingers.

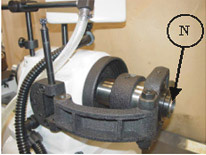

- Remove the collet closer as shown figure 12. Pull straight out end of spindle. Do not turn adjusting nut "N" (Figure 10), it is keyway to spindle. And do not remove collet closer by removing screw "S" (Figure 11) because these screws are adjusted at the manufacturer for proper operation of collet closer.

J.) COLLET CLOSER REPLACEMENT

Replace the collet closer first, must clean inside of the headstock spindle and outside diameter at rear of spindle where located adjusting nut "N" (Figure 13), apply a film of light oil on there. Do not force adjusting nut "N" (Figure 13) on spindle. If adjustment nut "N" (Figure 13) goes on tight, remove and check for burrs or scratches, then clean collet closer tube inside and outside apply a film of light oil on slip surface "T" (see figure 14) of the collet closer tube, replace collet closer and insert link pin "L" (figure 14).

K.) TO ADJUST COLLET CLOSER

- Before using the collet or step chuck and closer to the spindle, collet or step chuck and spindle should be clean.

- Push in lock pin "E" (Figure 15). To engage lock pin, turn spindle by hand till lock pin enter notch to lock.

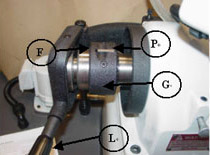

- Closer adjusting finger "F" (Figure 16) by pressing down at point "P" (Figure 16).

- Place collet closer tube on collet or step chuck until engaged. To turn the collet closer tube and turn the shell guard "G" (Figure 16) forward with operator's left hand while holding the collect or step chuck on place with operator's right hand.

- Place a work piece in collet or step chuck.

- Place lever "L" (Figure 16) to the extreme left or closed position. Turn shell guard "G" toward operator until the collet touch the piece.

- Place lever "L" (Figure 16) to the right (released) position. And turn shell guard "G" (Figure 16) toward operator, move the adjusting finger "F" (Figure 16) advances two notches on the adjusting nut "N" (Figure 17) and close adjusting finger "F" (Figure 16).

- Test collet closer for tension on work piece. If the gripping pressure required additional, open adjusting finger "F" (Figure 16) and turn shell guard "G" (Figure 16) toward operator. The gripping pressure require less, turn shell guard "G" (Figure 16) away operator. (see figure 16).

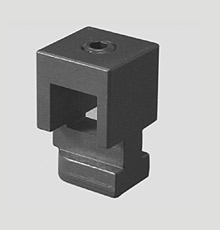

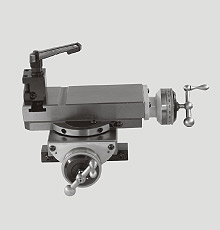

L.) COMPOUND SLIDE

The compound slide rest can be readily applied to the CYCLEMATIC Second Operation Machine for screw feed precision turning, facing and boring operations. The large diameter feed screws are hardened and mounted on preloaded ball bearings. The feed screw dials are 2" in diameter. Both dials give direct readings in thousandths and are adjustable for zero settings.

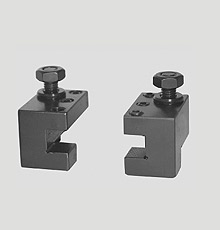

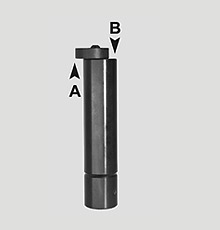

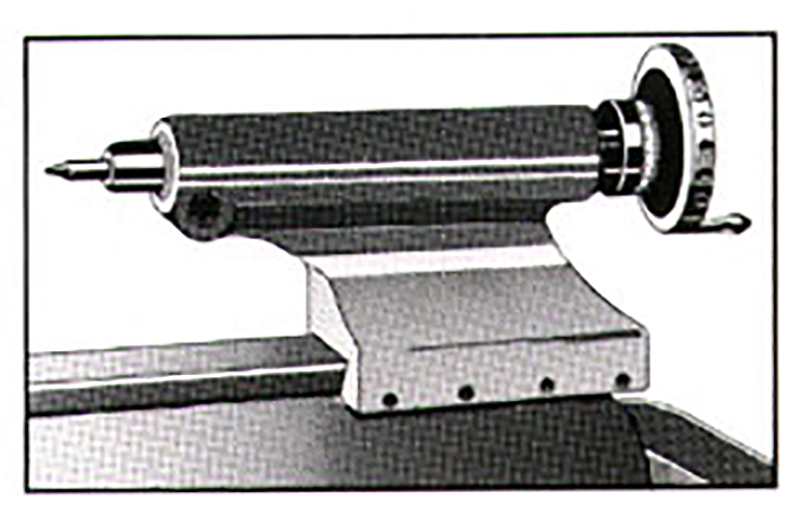

M.) TAILSTOCK

The tailstock is applied directly to the bed ways in place of the turret. It is ordered for center work.

N.) COOLANT FACILITIES

The machine is provided with coolant facilities required for high speed work. (Figure 21) The coolant pump is controlled by switch "G" (Figure 20) turn to "ON" position, pump will run continuously. Turn to "AUTO" position, pump will run only when machine is running. If pump switch is set at "OFF" position, THE COOLANT PUMP IS OFF. Use screen cover to prevent fine chips or powder from falling into sump when cutting on cast iron or other powdery material without coolant

The tailstock is mounted on preloaded ball bearings and can support any load to the spindle. It is provided with a fine "feed" for accurate work. The spindle of the tailstock is graduated in eighths of an inch, and 1 mm and has a travel of 95mm (3-3/4") The hand wheel is dual dial Inch and Metric. Graduations are 0.02mm (0.001"). It is built for the operator's convenience of operation just turn the dial ring "D" (Figure 35) to the required location. It is unnecessary to tighten the dial rings. They are spring loaded, so a lock screw is not needed. Sliding cover cage exposes only the dial in use.

| ITEM | Part no. |

|---|---|

| 1-2 | T-CT-02 |

| 1-2 | T-CT-03 |

| 1-2 | T-CT-04 |

| 1-2 | T-CT-05 |

| 1-2 | T-CT-06 |

| 1-2 | T-202-2B |

| 1-2 | T-202-3B |

| 1-2 | T-202-4B |

| 1-2 | T-202-5B |

| 1-2 | T-202-6B |

| 1-3 | T-DCT-02 |

| 1-3 | T-DCT-03 |

| 1-3 | T-DCT-04 |

| 1-3 | T-DCT-05 |

| 1-3 | T-DCT-06 |

| 1-3 | T-203-2B |

| 1-3 | T-203-3B |

| 1-3 | T-203-4B |

| 1-3 | T-203-5B |

| 1-3 | T-203-6B |

| 2-1 | T-SS-1 |

| 2-1 | T-ES-1 |

| 2-1 | T-LS-1 |

| 2-2 | T-UCS-25 |

| ITEM | Part no. |

|---|---|

| 3-1 | T-CT-01 |

| 3-2 | T-304A |

| 3-2 | T-304B |

| 3-3 | T-FP-3B |

| 3-3 | T-FP-5B |

| 3-3 | T-FP-8B |

| 3-4 | T-FP-07B |

| 4-1 | T-317 |

| 4-1-1 | CHUCK |

| 4-1-1 | CHUCK |

| 4-1-1 | CHUCK |

| 4-1-1 | CHUCK |

| 4-2 | T-AP-07 |

| 4-3 | LT-01-109 |

| 4-4 | LT-01-108C |

| 5-1 | LT-01-110T |

| 5-2 | T-315 |

| 5-2-1 | KM-6 |

| 5-3 | S-5C |

| 5-7 | T-3SJ |

| 7-5 | TDC-6.5 |

| 7-5 | TDC-10EL |

| 7-5 | TDC-13EL |

| 7-5 | TDC-16H |

| ITEM | Part no. |

|---|---|

| 12-3 | T-KH-48 |

| 14-1 | 540-110 |

| 14-2 | 540-111 |

| 14-3 | 540-130 |

| 14-4 | C20-ER20 |

| 15-1 | T-301 |

| 16-5 | L-40T |

| 17-2 | T-RT-208 |

| 18-3 | T-AIT-06 |

| 20-2 | CHR-68-12 |

| 20-3 | CTS-27-07 |

| 21-1 | CTS-27-08 |

| 21-2 | CTS-27-10 |

| 21-3 | CTS-27-11 |

| 21-4 | CTS-27-09 |

| 22-1 | T-CS-10 |

| 22-2 | T-MC-2 |

| 22-3 | T-LC-2 |

| 22-4 | T-DC13-MT2 |

| 22-4 | T-DC16-MT2 |

| 22-4 | T-DC19-MT2 |

| 22-5 | HQ32122-5 |

| 1-27MM | |

SPINDLE TOOLING, TOOLING HOLDER AND OPTIONAL EQUIPMENT FOR CYCLEMATIC HIGH SPEED. HIGH ACCURACY TOOLROOM LATHES

X-Z Axis compound slide standard on CTL-27EVS

The saddle slideway is coated with Turcite-B for maximum wear resistance.

The cross slideways have hardened and ground tool steel inserts for smooth accurate movement.

Screw feed tailstock standard on CTL-27EVS

The saddle slideway is coated with Turcite-B for maximum wear resistance.

The cross slideways have hardened and ground tool steel inserts for smooth accurate movement.